3/19/2025

| Dr. Andreas Eich

This article is about glass capillary viscometers. These are used to measure the viscosity of Newtonian fluids. Important standards in this context are ASTM D445, the new DIN 53000 and ISO 3104.

Glass capillary viscometers compared to other viscosity measuring devices

Glass capillary viscometers are used to measure the viscosity of Newtonian fluids. Important standards in this context are ASTM D445, the new DIN 53000 and ISO 3104. There are various designs for this, such as Ostwald, Cannon-Fenske and the particularly accurate Ubbelohde viscometers (suspended level viscometers), for which we would like to refer you to a separate blog post:

Glass capillary viscometers are used to measure the viscosity of Newtonian fluids. Important standards in this context are ASTM D445, the new DIN 53000 and ISO 3104. There are various designs for this, such as Ostwald, Cannon-Fenske and the particularly accurate Ubbelohde viscometers (suspended level viscometers), for which we would like to refer you to a separate blog post:

Read now

However, there are also measuring devices for viscosity that are based on other measuring techniques which admittedly often lead to viscosity results more quickly and easily: Determining kinematic viscosity with a capillary viscometer takes around 30 minutes including pre-tempering the sample, measuring with typically 3 cycle times and cleaning the viscometer. Other measuring devices, e.g. those that work according to ASTM D7042, require less time. In this competitive environment, the question arises as to the advantages of capillary viscometry. One advantage, which we will discuss in this article, is the accuracy and durability of viscometer calibration.

Borosilicate glass

Glass capillary viscometers are manufactured according to standard specifications from borosilicate glass 3.3 - a material that is characterized by excellent chemical resistance and a low coefficient of thermal expansion. As explained below, both properties lead to decisive advantages with regard to calibration.

Calibration and viscometer constant of capillary viscometers

Calibration provides the relationship between the primary measured variable and the viscosity derived from it. Such a calibration must be carried out for all types of viscometers. The measurement uncertainty of the determined viscosity naturally depends on the calibration and cannot be less than this.

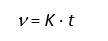

In the case of capillary viscometers, the calibration provides the relationship between the measured flow time t and the calculated kinematic viscosity n. For sufficiently long flow times, which are specified in the standards for capillary viscometry, this relationship is linear[1],and a viscometer constant, also known as the calibration constant, is obtained:

The unit of kinematic viscosity is usually mm2/s, the time is measured in seconds, so that the unit of the viscometer constant is, mm2/s2. The viscometer constant is a device constant and is linked to the serial number of the viscometer, which we refer to as the apparatus number (App.Nr.).

Validity period of a calibration

The question is often asked as to how long the viscometer constant is valid and when it needs to be recalibrated. Unfortunately, there is no universal answer to this question. Of course, this has to do with the type of use: Neutral and acidic aqueous solutions do not attack the glass, or only to a negligible extent, as do most concentrated acids - such as concentrated sulphuric acid - and organic solvents.

Important exception: Alkaline solutions corrode borosilicate glass. Hydrofluoric acid and concentrated phosphoric acid (at high temperatures >100°C) are also corrosive, but the latter two chemicals do not play a role in the application.

Based on experience, DIN 53000-1 recommends a maximum period of 5 years until recalibration for Ubbelohde viscometers. Compared to many other measuring devices, this is a long period of validity. In the following, we will use a few examples to show whether changes to the viscometer constant can be expected during this period.

Examples of the durability of the calibration of individual viscometers

The manufacture of capillary viscometers in our company has a 50-year history

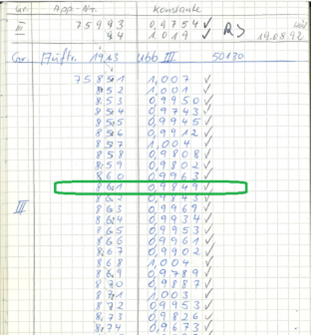

Handwritten documentation of the calibration in a calibration book from 1992

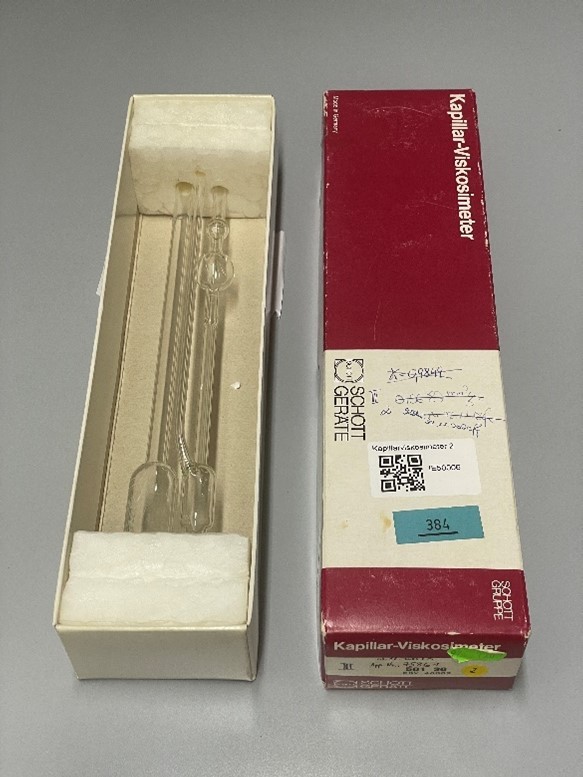

Some customers send their viscometers back to our calibration laboratory for recalibration after a long period of use. For these viscometers, this gives us the opportunity to track the change in calibration over the period of use. A particularly noteworthy example is the viscometer with the app. no. 75861, an

Ubbelohde viscometer according to DIN, type 501 30 /III. Our laboratory staff noticed this viscometer because of its unusual packaging, which we have not used for decades - and our apparatus numbers have been 7-digit rather than 5-digit for many years.

In this particular case, we searched in old documents and were able to find the calibration documentation, which was still handwritten at the time, in a calibration book: This viscometer was calibrated for the first time on August 19, 1992. The viscometer constant determined at that time was 0.9849 [mm2/s2].

Although the packaging clearly showed its age, the glass viscometer did not, as a visual inspection showed hardly any changes compared to a new viscometer.

Viscometer App.Nr. 75861 after 32 years in use

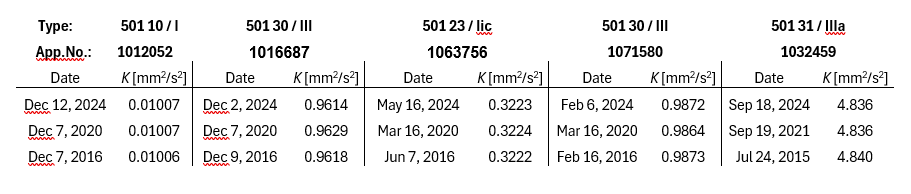

The recalibration on Nov 11, 2024 resulted in the viscometer constant K=0.9845. This is a negligible difference of 0.04% compared to the 32-year-old original value. The value is also within the measurement uncertainty of our standard calibration, which we conservatively specify as ±0.65% for the value of the viscometer constant (coverage factor k=2)[2].

This agreement is astonishing, but it is not a single case, it’s the rule. Further examples of the recalibration of viscometers with a less “biblical” age can be found in the table:

These viscometers were selected at random and the list could be continued. In the vast majority of cases, the changes in the calibration constant do not exceed the measurement uncertainty of ±0.65%, even after more than 5 years of use.

However, even with Ubbelohde viscometers, such high reproducibility and durability of calibration values cannot be taken for granted. In addition to a high-quality calibration process , they require thorough cleaning of the viscometers before calibration, as well as the avoidance of alkaline liquids during measurement and cleaning in the user's everyday measuring routine. [3]

Temperature dependence of the viscometer constant

In addition to the durability of the viscometer constant, another advantage of calibrating glass capillary viscometers should be emphasized: The value of K changes very little with temperature.

This is due to the low thermal expansion coefficient of borosilicate glass: 3 · 10-6 K-1.As the viscometer therefore changes only slightly with temperature, a temperature difference of 100 °C between calibration and measurement only leads to an error of less than 0.1 %. This is documented in DIN 53000-2, a standard that deals specifically with the error sources and corrections of viscosity measurements with glass capillary viscometers. A temperature difference of up to 100°C to the calibration temperature can therefore generally be neglected with regard to the change in the viscometer constant.

[1]For short flow times, a Kinetic Energy Correction (German: Hagenbach-Korrektion) must be determined and taken into account, especially for viscometers with narrow capillaries and when high accuracies are required. This is a separate topic and will not be described here.

[2]The measurement uncertainty of the viscometer constant depends on the effort required for calibration. Ubbelohde viscometers can be calibrated even more accurately than  = ±0.65%, which is carried out and offered commercially by some ISO 17025-certified calibration laboratories and national metrological institutes -- Learn more in the Master Ubbelohde blog.

= ±0.65%, which is carried out and offered commercially by some ISO 17025-certified calibration laboratories and national metrological institutes -- Learn more in the Master Ubbelohde blog.

[3]The specifications for the calibration of e.g. Ubbelohde viscometers according to DIN are given in DIN 53000-3.

Content:

- Viscosity - Rheology

- Fundamental of capillary viscometry

- Measurement of the flow time

- Method fordetermining viscosity

- Calibration

- and more...